Fuel injectors don’t fail loudly at first. They fail quietly through small power loss, rough running, extra smoke, and fuel that disappears faster than it should. In Abu Dhabi’s marine and power-generation work, those “small” symptoms quickly turn into real costs: delayed schedules, unstable output, and unexpected downtime.

That’s why you must manage fuel injector spare parts professionally. You need proper testing, correct calibration, and reliable components that match your engine. Whether you run a vessel, offshore equipment, or a diesel generator, you work toward the same outcome: stable performance, clean combustion, and dependable operation under load.

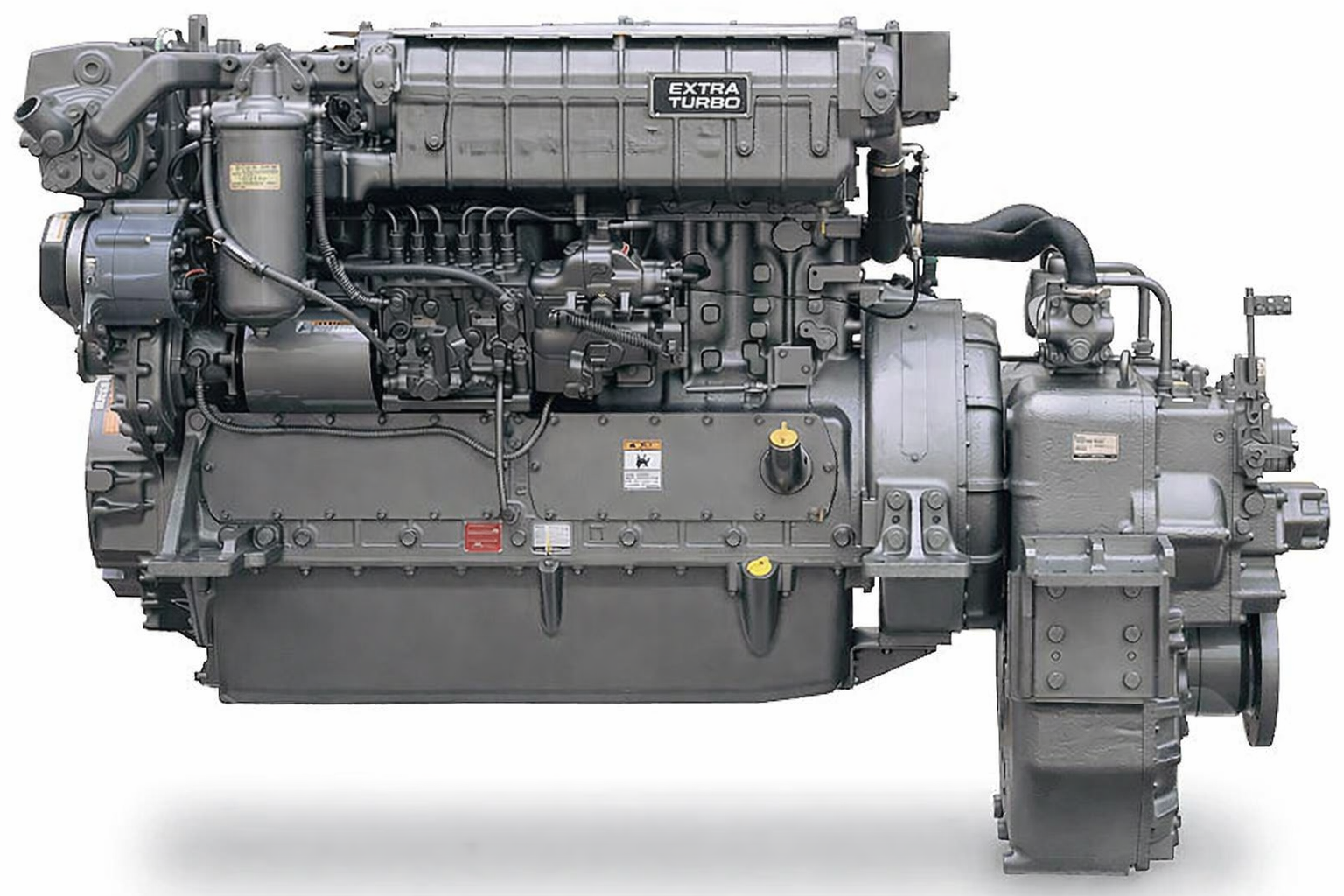

At JRS, we support operators with fuel injection systems and components including injector parts and complete assemblies built for demanding duty cycles.

Why Fuel Injectors Matter More Than Most Parts

A fuel injector’s job sounds simple: it delivers the right amount of diesel, at the right time, at the right pressure, in a fine spray. In practice, injectors operate under extreme heat and pressure, and they must hold very tight tolerances. Even minor wear or contamination can disrupt the spray pattern and fuel delivery, causing poor combustion, smoke, and reduced efficiency.

When injectors are healthy, you get:

- Smooth starting and stable RPM

- Cleaner combustion and lower smoke

- Better fuel efficiency

- Reliable power under load (especially for diesel generators)

Common Signs You Need Injector Testing or Repair

If you’re seeing any of these, your injectors (or the wider fuel system) need professional attention:

- Hard starting or delayed starting

- Rough idle / unstable RPM (hunting)

- Power drop under load

- Black/white smoke

- Increased fuel consumption

- Knocking sound or abnormal vibration

- Uneven cylinder temperatures or misfires

In generator applications, you may also notice unstable frequency/voltage because combustion is inconsistent.

What Professional Injector Repair Actually Includes

A proper injector repair involves more than cleaning. A workshop-grade process follows a structured, test-backed method:

- Calibration and bench testing: Technicians confirm performance by testing opening pressure, spray pattern, leakage, and response consistency under load. Only after the injector passes testing should it return to service.

- Inspection and strip-down: Technicians inspect injectors for external leaks, carbon build-up, damaged seats or threads, and heat-related wear.

- Precision cleaning: Technicians remove deposits using controlled cleaning methods suitable for injector components.

- Component evaluation: Technicians check critical wear points such as the nozzle, needle, springs, sealing surfaces, and internal leakage paths.

- Replacement with correct injector spare parts: Technicians replace worn components with injector spare parts that match the injector model and engine specifications.

Fuel Injector Spare Parts: What Operators Commonly Need

Your injector type (mechanical or electronic) determines which spare parts you may need, such as:

- Nozzles

- Needle/seat components

- Springs and internal hardware

- Seals, O-rings, and washers

- Complete injector assemblies (when rebuilding is not cost-effective)

For high-uptime operators, you must keep cylinder performance consistent. Uneven injection can create unstable load handling, vibration, smoke, and unnecessary stress on the engine, especially in marine and power-generation duty cycles.handling and faster engine wear.

Don’t Ignore the System: Pumps, Pressure, and Fuel Quality

Injectors work as part of a larger fuel system. Many injector problems keep coming back because another component causes the real issue, such as:

- A worn fuel injection pump that creates unstable pressure

- Dirty fuel, water contamination, or poor filtration

- Incorrect timing or poor calibration

- Damaged high-pressure lines or leaking fittings

That’s why you should evaluate injector repair together with fuel pump performance and filtration condition especially for marine and power-generation duty cycles.

Marine vs Diesel Generator: What Changes in Injector Requirements?

Marine engines often face

- Long running hours

- Salt air exposure and temperature swings

- Variable loading (harbour manoeuvres vs cruising)

Diesel generators often face

- Frequent start/stop cycles (backup power) or continuous duty (prime power)

- Load steps that demand stable fuel delivery

- Output stability requirements for critical systems

In both cases, injector calibration must suit the application not just the part number.

Why Choose JRS for Fuel Injector Spare Parts and Repair Support?

Operators choose JRS for results that reduce downtime and protect engine reliability:

- Right parts for the right engine: Support for injector components and assemblies aligned with marine and power-generation requirements.

- System-level approach: Injectors are handled as part of the complete fuel injection chain, helping reduce repeat faults.

- Operational focus: The objective is measurable, stable running, reduced smoke, better fuel economy, and fewer breakdowns.

Ready to Fix Injector Issues and Reduce Downtime?

Fuel injector issues don’t stay small. In marine and generator operations, they quickly turn into downtime, fuel loss, and operational risk. A structured approach using quality fuel injector spare parts, proper testing, and correct calibration restores performance and protects your engine over the long run.

Need injector parts or support in Abu Dhabi? Connect with JRS for fuel injection components and expert assistance tailored to marine and power-generation applications.